Some notes taken in discussion with Alan Hills about the workings of the clay pits at Shorne Woods. Alan worked in the Clay Pit from 1959 – 1963.

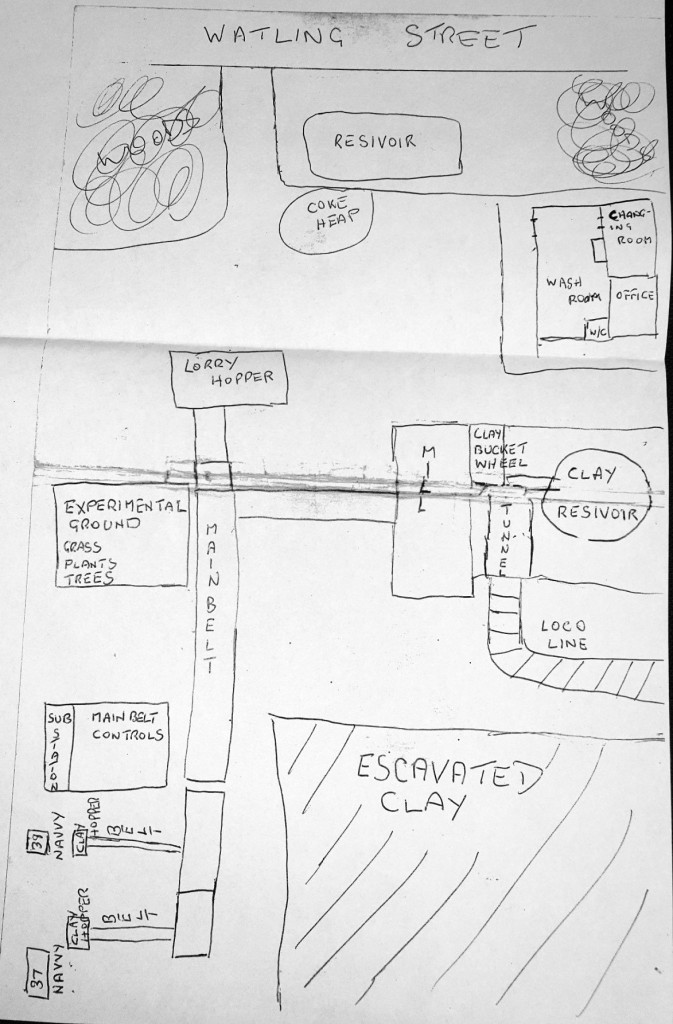

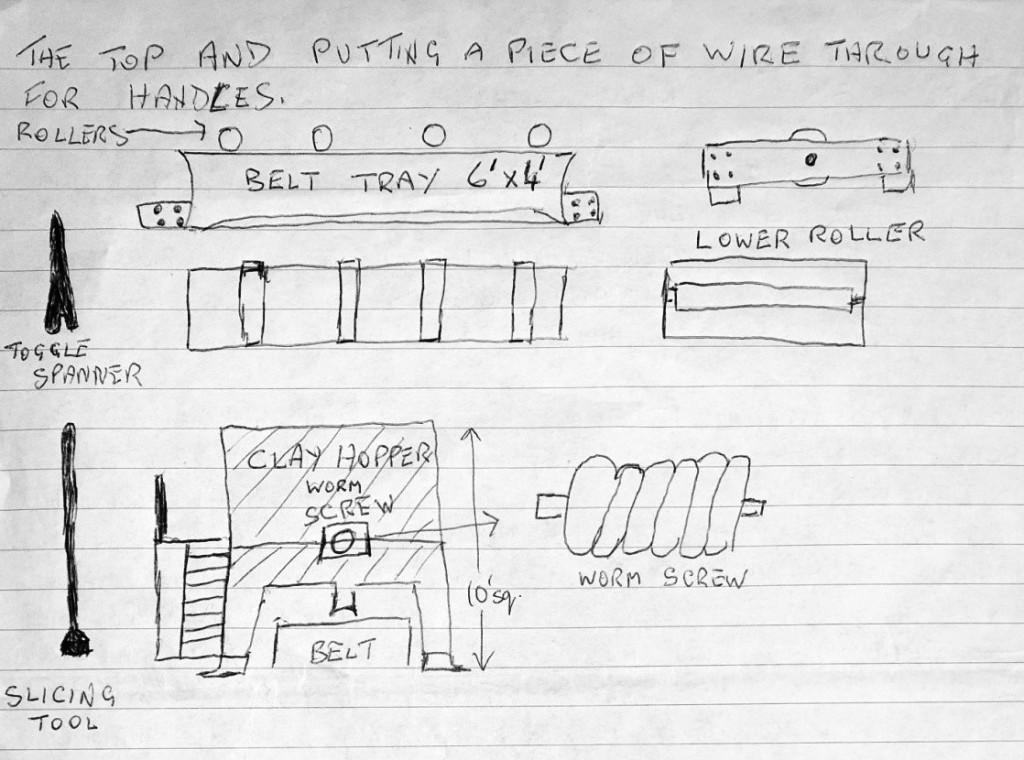

Navvy Driver load clay into hopper which had a screw blades rotating, breaking clay into workable size for running it through to the conveyor belt from the pit face to the main belts running down to the washmill. When the mill had got its quota, the Millers Mate would switch over to the lorry hopper and fill it to transport to the Crown & Quarry Works at Strood. 2 lorries would shuttle clay day & night. About 16 to 20 over 24 hrs. depending on the quality of the clay.

Wash out were done when the rocks and debris clogged up the tynes, preventing the mill from turning. The wagons are shunted under the mill through a tunnel and trapdoor is opened and the Miller puts the mill in low gear to allow the debris to fall into the wagons and the Loco pulls wagons up to the wash-out road tipped out.

The Navvy crews would check the belts and get any equipment ready for extending the face belt e.g. trays, new belt, belt ratchet, timbers.

All workers were supplied thigh wellington boots, gloves (industrial) and duffle coats.

Make our billycans were made from baby milk tins and our water cans were made from sweet tins, as they were larger by punching two holes near the top and putting a piece of wire through for handles.

Alan worked at the site between 1959 and 1963. Had been on the Tilbury beforehand. The money at the site was relatively good. His father had worked there too. Mr Hills went off to work at ? after the site closed in 1964 or 5.

The site operated 7 days a week, continuously. Shifts were from 6am – 2pm, 2 – 10pm and then 10pm – 6am. Sometimes those working on the dry clay did 12-hour shifts.

The clay was sent off site as dry or wet clay.

The clay hoppers were about 10 ft square.

Used a small diesel loco onsite – gauge unknown.

Dry clay was put into the lorry hopper to be taken away off site.

Chap nicknamed Mutton – belt had blown off the conveyor, so he stood on it to tie it back onto the rollers. A gust of wind caught the belt, somersaulted Mutton who landed badly & dislocated his shoulder. But it could have been a lot worse because he landed in a pile of clay which cushioned him!!

Spud Taylor manned the pumping station at Tollgate. The workers rang him when the clay was coming through.

Len Jarrett was a navvy driver.

Roles on site included: Shift workers, Day workers, General Foreman, Foreman, Miller, Miller’s Mate, Navvy driver, Hopper attendant, Electrician (from Fitter Crown & Quarry), Main Belt attendant, Belt attendant, General duties man, contract labourers